Choosing a capacitor depends on three factors:

- Voltage (in volt: V)

- Capacitance (microfarad: μF)

- Application (permanent or start)

Note: Motors can feature one or two capacitors. If they only have one capacitor, it must be permanent.

When handling or operating capacitors, you have to make sure they are discharged. An eletric shock may occcur since capacitors load cannot be seen. It is possible to control it with a voltage absence tester (VAT) or a voltmeter.

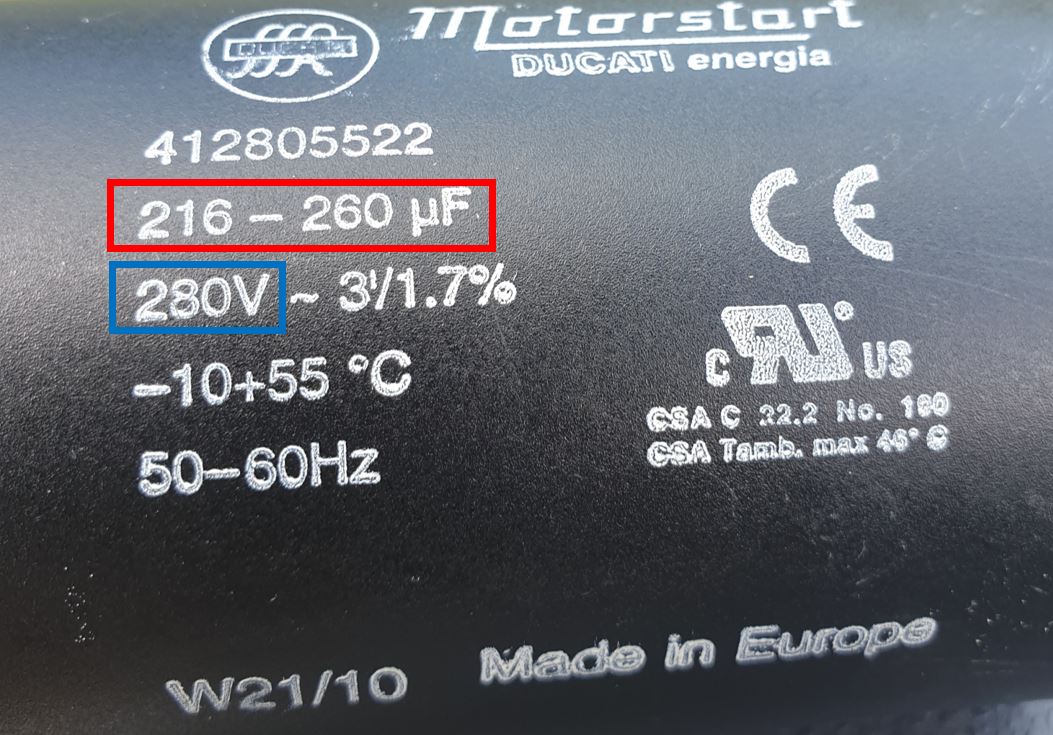

When the capacitor is disassembled, you should read voltage and capacitance instructions as shown in the example:

Note: the difference between a permanent capacitor and a start capacitor lie in their characteristics. A permanent capacitor has a set capacitance, in opposition to a start capacitor which has a range of capacitance.

This capacitor is in 280V and has a capacitance from 216 to 260μF, which defines it as a start capacitor. This product is available on Easi-Spare under the reference COMST320200_250.

If you cannot read the information anymore, please refer to the manufacturer’s technical datasheets. Capacitors specifications required to operate the motor are written there.

To go further:

To convert a three-phase motor into a single-phase motor, you have to use a permanent capacitor and not a start capacitor.

For this operation, we recommend you to take a look at blog Gégé la bobine (French website) which explains the conversion.

Blog

Blog